Magicians work in the manufacturing industry today. At least, that’s the way it would seem to builders and inventors of past centuries. Imagine if they could see a machine that created three-dimensional objects on demand. They would surely think it was wizardry. It’s easy for us to take 3D printing for granted, but you should give it a second look.

As part of the additive manufacturing process, 3D printing allows manufacturers to generate innovative and cost-effective parts. Additive manufacturing (also known as AM) is emerging as one of the hottest trends in the industry. Here’s a look at how it’s changing the world of manufacturing and its job market.

What is Additive Manufacturing?

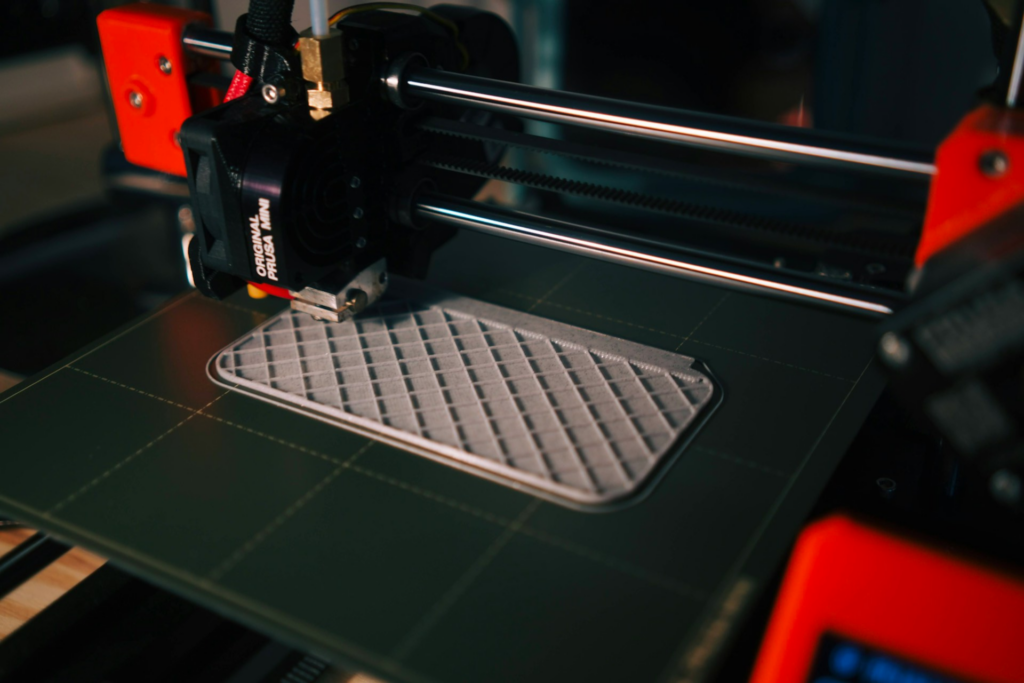

So, what is additive manufacturing? It’s essentially a process of creating three-dimensional objects by sequentially adding material layer after layer. The AM process is based on a digital model, which can be made with several popular CAD and drawing apps.

The term “additive manufacturing” is often used as a synonym for “3D printing,” but that’s an oversimplification. 3D printing is just one part of the AM process, which includes a whole production process, from material preparation to post-processing of finished products.

When industry people refer to AM, they’re not talking about just the printing. They’re referring to a new process that doesn’t follow traditional subtractive manufacturing methods. Whereas the standard manufacturing processes involve cutting or removing material, AM adds on, layer by layer, until the product is finished.

Initially used for rapid prototyping, AM has now expanded into production lines in many sectors. This includes aerospace, where complex lightweight components are printed for aircraft and spacecraft. In the medical field, AM helps create patient-specific implants and prosthetics. The automotive industry is utilizing AM for customized parts and tooling. Even in the consumer goods sector, you’ll find 3D-printed jewelry, eyewear, and footwear.

The Benefits and Challenges of Additive Manufacturing

AM is reshaping the industry because of its benefits to manufacturing organizations. Beyond the highly customized products, there are significant cost savings. AM minimizes waste compared to traditional methods by only using the necessary material. Prototypes and final products can be produced much faster, accelerating product development cycles. AM also makes intricate designs that were once impossible to manufacture a reality.

While additive manufacturing holds immense promise, it’s not without its challenges. The range of materials suitable for AM is still expanding, limiting some applications. Ensuring consistent quality across printed parts requires robust processes and standards. While costs are decreasing, some AM technologies remain expensive for widespread adoption. The digital nature of AM design also means hiring leaders must find workers with tech skill sets new to the manufacturing industry.

Hiring for the New Additive Manufacturing Roles

Hiring managers and HR teams must now recruit for jobs that didn’t exist just a few years ago. One of the most in-demand roles is the 3D printing technician. These workers operate and maintain 3D printers. Technicians must have a broad set of skills, including knowledge of production processes and equipment maintenance. The complex workings of 3D printers require technicians to be handy with small parts when things break down.

The US Bureau of Labor Statistics sees the demand for 3D printing technicians growing by 13% through 2030. That’s much faster than the average job role, which typically grows at rates less than 5%.

Also in demand are CAD and CAM designers who are fluent in digital models. While many designers are available with traditional CAD skills, not all have experience in the digital realm. The ability to build additively in a digital space is a unique skill, one that’s needed for successful additive manufacturing.

Manufacturing organizations also need materials engineers who can develop specifically for AM’s unique materials. There’s also a strong demand for quality control specialists who can properly evaluate 3D-printed materials for durability and reliability. Whereas products created through subtractive manufacturing typically break down into discrete parts, 3D-printed objects may not. This requires a whole new QC skill set.

Additive Manufacturing and Other Industry Changes

Additive manufacturing will continue to become more commonplace in the industry. It’s simply too cost-effective and innovative to be a fad. In fact, you can consider it modern wizardry. That means hiring managers must work with magic on the job market to find more specialized talent.

The future is bright for both manufacturers looking to adopt AM and workers seeking a career in the industry. But it’s just one of many trends changing the shape of manufacturing. To stay on top of the trends in a broad range of fields, follow MRINetwork.

Connect with MRINetwork