Efficient plant operations can give your business a considerable advantage over its competitors. While plenty of industries have already started the digital transformation process, you might wonder whether the technology has a place within your facility.

In this guide we’ll discuss how manufacturing plants can use digital technologies to streamline processes, improve collaboration, avoid malfunctions, and lower expenses. You’ll almost certainly find something that fits into your plant.

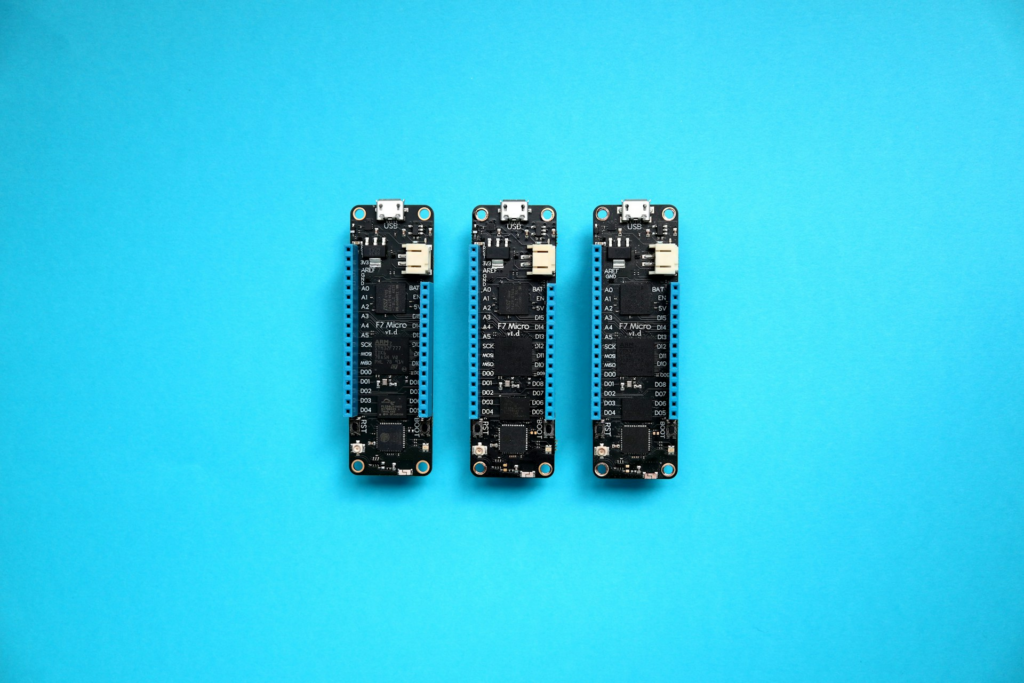

Implementing IoT Devices for Real-Time Monitoring

The Internet of Things (IoT) makes it possible for a broad range of devices to communicate with each other. Some manufacturing facilities use IoT to collect data in real-time. Popular strategies include:

- Monitoring temperatures to avoid extremes that could damage products or machines

- Analyzing the steps in manufacturing products to discover more efficient techniques

- Tracking materials so employees can locate them quickly

- Detecting defects that could interrupt processes or damage the company’s reputation

- Auditing safety checkpoints to prevent accidents and improve security

IoT is a rapidly advancing technology. Adopting it now will help you discover new ways it can benefit your plant operations.

Using Cloud-Based Software for Data Storage and Analysis

Storing data at your location is potentially expensive and risky. Anything from a weather event to human error could put your data in jeopardy. Moving information to the cloud helps solve those problems. Instead of hosting the data in a single location, you distribute it throughout multiple cloud servers. Your cloud service provider should do this automatically, so you don’t need extra skills. It certainly helps to have an IT professional on staff, though.

The cloud also makes it easier for your team to analyze massive amounts of data. Instead of investing in the servers required to host big data, you can keep information in the cloud and rely on cloud-based apps to analyze it. Use the analytics to make plant operations more efficient so you can increase productivity and lower costs.

Integrating AI Algorithms for Predictive Maintenance

Preventive maintenance helps protect your company’s investments. You might have spent millions on manufacturing equipment, so you want it to last as long as possible.

You probably already have a maintenance schedule that your employees follow. Unscheduled maintenance, however, addresses issues as they emerge. Unfortunately, it’s very difficult for humans to select the right time for unscheduled maintenance. All too often, you don’t know you need it until something breaks.

AI algorithms can monitor every aspect of your plant operations to detect aberrations that suggest mechanical problems. Maybe one machine vibrates a little harder than the others. A person can’t measure the small difference, but AI algorithms can monitor data constantly. If anything looks abnormal, a well-trained algorithm will notice.

Automating Routine Tasks With RPA Solutions

Repetitive tasks cause a lot of problems for people. When you do the same thing over and over, your mind can drift and put you at risk of making a mistake. Instead of assigning repetitive, boring work to a person, you can let robotic process automation (RPA) handle it.

RPA might sound like it does work on your manufacturing floor. It isn’t about physical robots, though. RPA refers to software that automates routine tasks by following simple directions. For example, you might use RPA solutions to:

- Maintain accurate invoices

- Record the locations of completed products

- Ensure employees get paid correctly for the number of hours they worked

- Track supplies as they move from one place to another

If a task follows “if this, then that” logic, RPA can likely help.

Enhancing Communications and Collaboration Through Digital Platforms

Plant operations is a collaborative process that requires a lot of communication. Traditionally, managers and executives have accomplished goals by gathering in meeting rooms. That approach, however, takes a lot of time and energy. While you might want to hold meetings to discuss some topics, you don’t need face-to-face conversations to improve most of your plant operations.

Digital platforms provide a low-cost, fast way for people to communicate and collaborate. Teleconferencing probably comes to mind. Instead of getting on a plane to meet with managers at another facility, you can connect with them remotely from your office.

Digital communication goes much deeper than videoconferencing, though. Some software options will let you:

- Collaborate on design ideas with other professionals

- Communicate progress by moving tasks from one folder (“planned”) to another (“in review”)

- Store important documents in a single location where authorized personnel can access them as needed

Whether you want to hold a meeting or track productivity, the right digital platform can make your job easier.

The Evolving Role of Digital Technology in Plant Operations

Technology improves rapidly, so it’s important to keep learning about new ways you can use emerging features in your facility.

Follow MRINetwork to keep up with the most recent ways technology can improve plant operations.

Connect with MRINetwork